FootPrintKu

FootPrintKu

FootPrintKu

FootPrintKu

Branding & UI Design

Branding & UI Design

Branding & UI Design

To comply with NDA's and PIAA's, I have omitted and redacted confidential information in my project showcase. All information in this case study is my own and does not necessarily reflect the views of FootPrintKu

To comply with NDA's and PIAA's, I have omitted and redacted confidential information in my project showcase. All information in this case study is my own and does not necessarily reflect the views of FootPrintKu

To comply with NDA's and PIAA's, I have omitted and redacted confidential information in my project showcase. All information in this case study is my own and does not necessarily reflect the views of FootPrintKu

To comply with NDA's and PIAA's, I have omitted and redacted confidential information in my project showcase. All information in this case study is my own and does not necessarily reflect the views of FootPrintKu

CONTEXT

CONTEXT

CONTEXT

CONTEXT

CONTEXT

FootPrintKu is a SaaS start-up with a cloud-based platform that automates the labor intensive tasks involved in building schematic symbols, printed circuit board footprints, and 3D models plaguing the hardware industry. Through automation, the platform is able to convert PDF data sheets that hardware engineers receive from component companies into working software files. The engineers can then easily design and verify how their products would work with programs such as Cadence's Allegro and CAD software such as Solidworks.

The goal was to launch the company's flagship platforms and to successfully market the company's brand and message to the hardware electronics industry.

FootPrintKu is a SaaS start-up with a cloud-based platform that automates the labor intensive tasks involved in building schematic symbols, printed circuit board footprints, and 3D models plaguing the hardware industry. Through automation, the platform is able to convert PDF data sheets that hardware engineers receive from component companies into working software files. The engineers can then easily design and verify how their products would work with programs such as Cadence's Allegro and CAD software such as Solidworks.

The goal was to launch the company's flagship platforms and to successfully market the company's brand and message to the hardware electronics industry.

FootPrintKu is a SaaS start-up with a cloud-based platform that automates the labor intensive tasks involved in building schematic symbols, printed circuit board footprints, and 3D models plaguing the hardware industry. Through automation, the platform is able to convert PDF data sheets that hardware engineers receive from component companies into working software files. The engineers can then easily design and verify how their products would work with programs such as Cadence's Allegro and CAD software such as Solidworks.

The goal was to launch the company's flagship platforms and to successfully market the company's brand and message to the hardware electronics industry.

FootPrintKu is a SaaS start-up with a cloud-based platform that automates the labor intensive tasks involved in building schematic symbols, printed circuit board footprints, and 3D models plaguing the hardware industry. Through automation, the platform is able to convert PDF data sheets that hardware engineers receive from component companies into working software files. The engineers can then easily design and verify how their products would work with programs such as Cadence's Allegro and CAD software such as Solidworks.

The goal was to launch the company's flagship platforms and to successfully market the company's brand and message to the hardware electronics industry.

FootPrintKu is a SaaS start-up with a cloud-based platform that automates the labor intensive tasks involved in building schematic symbols, printed circuit board footprints, and 3D models plaguing the hardware industry.

Through automation, the platform is able to convert PDF data sheets that hardware engineers receive from component companies into working software files. The engineers can then easily design and verify how their products would work with programs such as Cadence's Allegro and CAD software such as Solidworks.

The goal was to launch the company's flagship platforms and to successfully market the company's brand and message to the hardware electronics industry.

PROJECT ROLE

PROJECT ROLE

PROJECT ROLE

PROJECT ROLE

PROJECT ROLE

I was brought on for additional design direction for redesigning the user interface and experience of this project. The core team worked in Asia, and did not have much experience designing for a U.S centric market. This meant making workable prototypes, and providing branding guidelines and marketing materials for tradeshows.

I worked alongside a product manager, marketing administrator, as well as external marketing agencies. In addition, I also worked with designers and engineering team overseas where the bulk of the development and implementation is done.

I was brought on for additional design direction for redesigning the user interface and experience of this project. The core team worked in Asia, and did not have much experience designing for a U.S centric market. This meant making workable prototypes, and providing branding guidelines and marketing materials for tradeshows.

I worked alongside a product manager, marketing administrator, as well as external marketing agencies. In addition, I also worked with designers and engineering team overseas where the bulk of the development and implementation is done.

I was brought on for additional design direction for redesigning the user interface and experience of this project. The core team worked in Asia, and did not have much experience designing for a U.S centric market. This meant making workable prototypes, and providing branding guidelines and marketing materials for tradeshows.

I worked alongside a product manager, marketing administrator, as well as external marketing agencies. In addition, I also worked with designers and engineering team overseas where the bulk of the development and implementation is done.

I was the brought on for additional design direction for redesigning the user interface and experience of this project. The core team worked in Asia, and did not have much experience designing for a U.S centric market. This meant making workable prototypes, and providing branding guidelines and marketing materials for tradeshows.

I worked alongside a product manager, marketing administrator, as well as external marketing agencies. In addition, I also worked with designers and engineering team overseas where the bulk of the development and implementation is done.

I was the brought on for additional design direction for redesigning the user interface and experience of this project. The core team worked in Asia, and did not have much experience designing for a U.S centric market. This meant making workable prototypes, and providing branding guidelines and marketing materials for tradeshows.

I worked alongside a product manager, marketing administrator, as well as external marketing agencies. In addition, I also worked with designers and engineering team overseas where the bulk of the development and implementation is done.

CHALLENGES

CHALLENGES

CHALLENGES

CHALLENGES

CHALLENGES

In the hardware industry, an engineer could spend countless hours building schematic symbols, printed circuit board footprints, and 3D models of common components before they could start the actual product design. Jobs like these are also becoming increasingly specialized, due to students going into the software industry rather than the hardware industry. Which meant that even though this product was targeted for seasoned engineers, it also had to be usable by those fresh out of college.

The challenge for this project was to emphasize a clear message—that the engineers whose livelihoods were tied to these repetitive manual tasks wouldn’t lose their jobs from an automated platform. Instead, the platform will free up time for the engineers to focus on work that actually matters.

In addition, FootPrintKu had to position the product in a way as to not alienate other partner software companies in the hardware design production pipeline.

In the hardware industry, an engineer could spend countless hours building schematic symbols, printed circuit board footprints, and 3D models of common components before they could start the actual product design. Jobs like these are also becoming increasingly specialized, due to students going into the software industry rather than the hardware industry. Which meant that even though this product was targeted for seasoned engineers, it also had to be usable by those fresh out of college.

The challenge for this project was to emphasize a clear message—that the engineers whose livelihoods were tied to these repetitive manual tasks wouldn’t lose their jobs from an automated platform. Instead, the platform will free up time for the engineers to focus on work that actually matters.

In addition, FootPrintKu had to position the product in a way as to not alienate other partner software companies in the hardware design production pipeline.

In the hardware industry, an engineer could spend countless hours building schematic symbols, printed circuit board footprints, and 3D models of common components before they could start the actual product design. Jobs like these are also becoming increasingly specialized, due to students going into the software industry rather than the hardware industry. Which meant that even though this product was targeted for seasoned engineers, it also had to be usable by those fresh out of college.

The challenge for this project was to emphasize a clear message—that the engineers whose livelihoods were tied to these repetitive manual tasks wouldn’t lose their jobs from an automated platform. Instead, the platform will free up time for the engineers to focus on work that actually matters.

In addition, FootPrintKu had to position the product in a way as to not alienate other partner software companies in the hardware design production pipeline.

In the hardware industry, an engineer could spend countless hours building schematic symbols, printed circuit board footprints, and 3D models of common components before they could start the actual product design. Jobs like these are also becoming increasingly specialized, due to students going into the software industry rather than the hardware industry. Which meant that even though this product was targeted for seasoned engineers, it also had to be usable by those fresh out of college.

The challenge for this project was to emphasize a clear message—that the engineers whose livelihoods were tied to these repetitive manual tasks wouldn’t lose their jobs from an automated platform. Instead, the platform will free up time for the engineers to focus on work that actually matters.

In addition, FootPrintKu had to position the product in a way as to not alienate other partner software companies in the hardware design production pipeline.

In the hardware industry, an engineer could spend countless hours building schematic symbols, printed circuit board footprints, and 3D models of common components before they could start the actual product design.

Jobs like these are also becoming increasingly specialized, due to students going into the software industry rather than the hardware industry. Which meant that even though this product was targeted for seasoned engineers, it also had to be usable by those fresh out of college.

The challenge for this project was to emphasize a clear message—that the engineers whose livelihoods were tied to these repetitive manual tasks wouldn’t lose their jobs from an automated platform. Instead, the platform will free up time for the engineers to focus on work that actually matters.

In addition, FootPrintKu had to position the product in a way as to not alienate other partner software companies in the hardware design production pipeline.

DEFINING THE PRODUCT

DEFINING THE PRODUCT

ANALYSIS

DEFINING THE PRODUCT

DEFINING THE PRODUCT

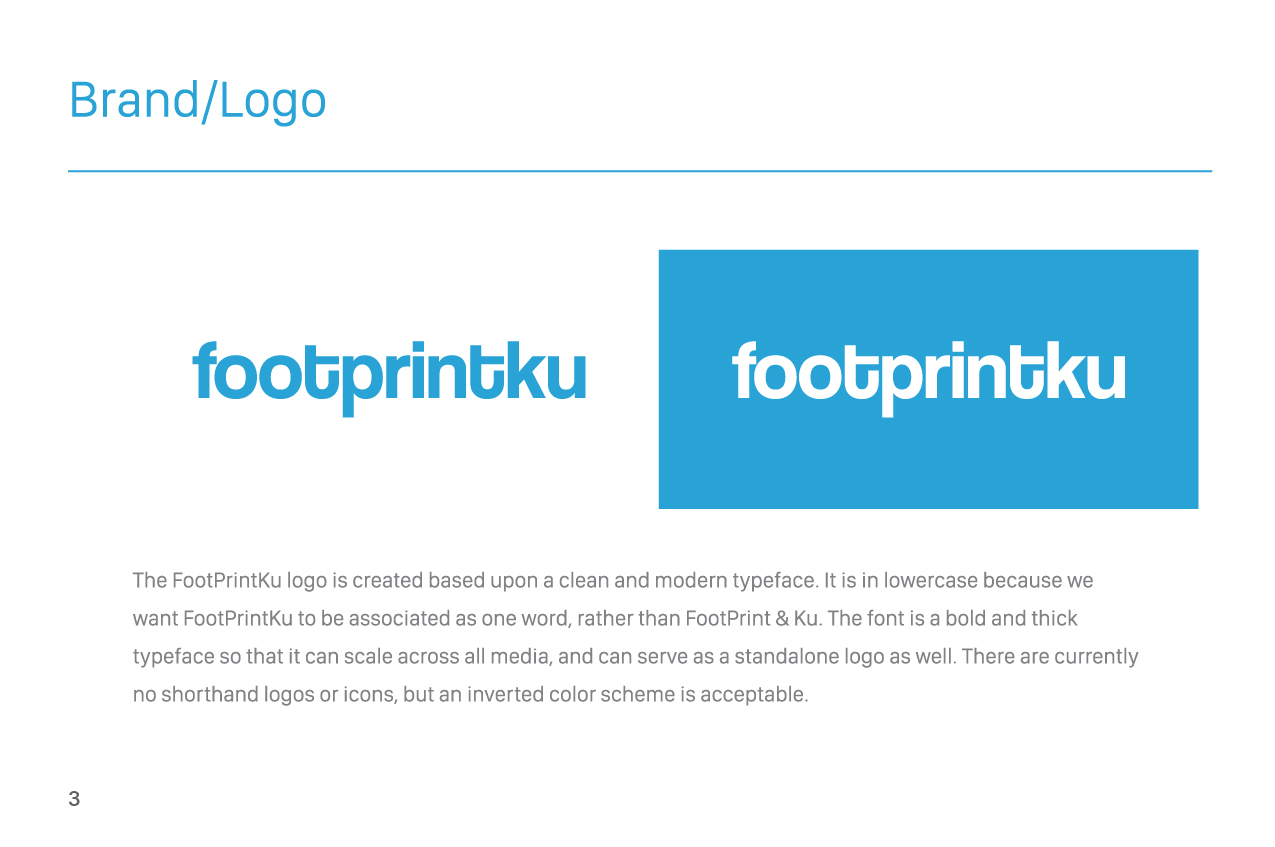

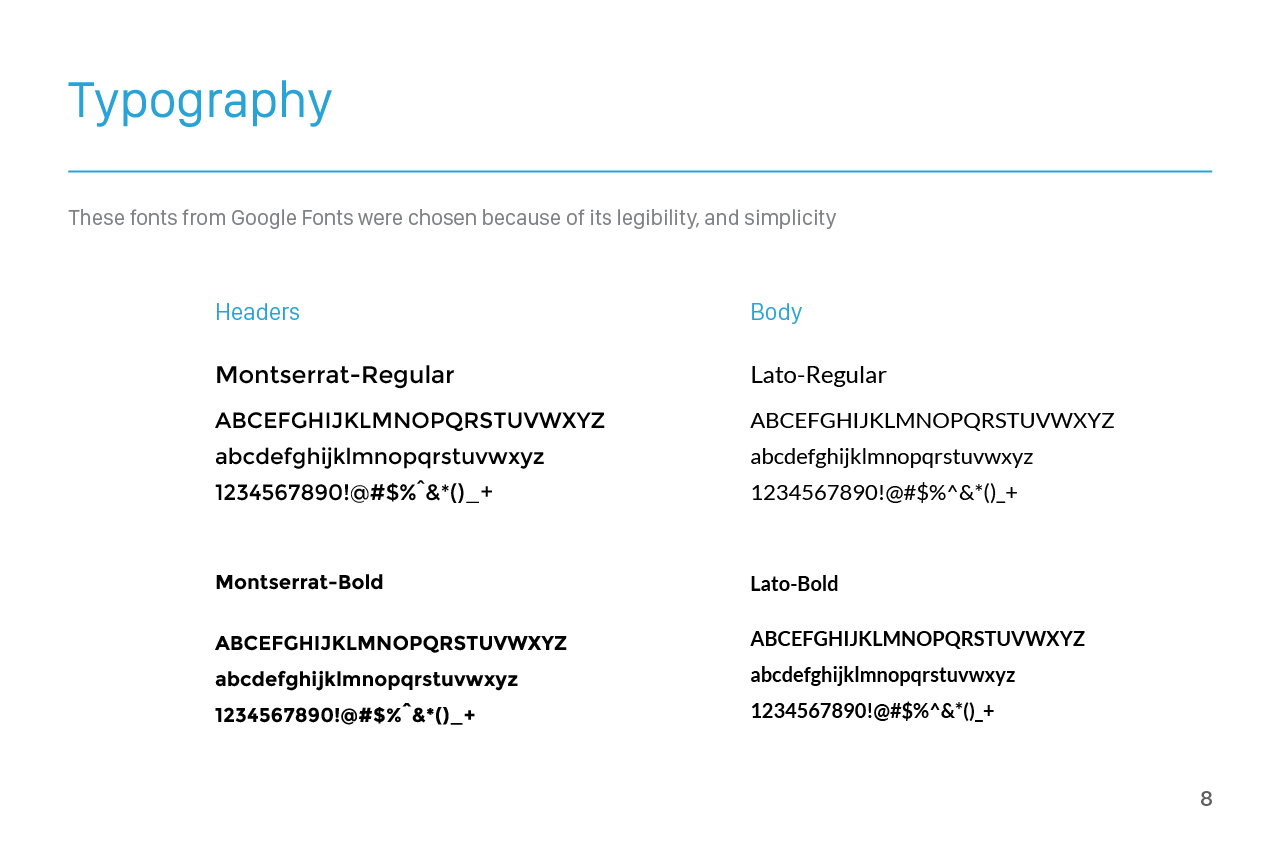

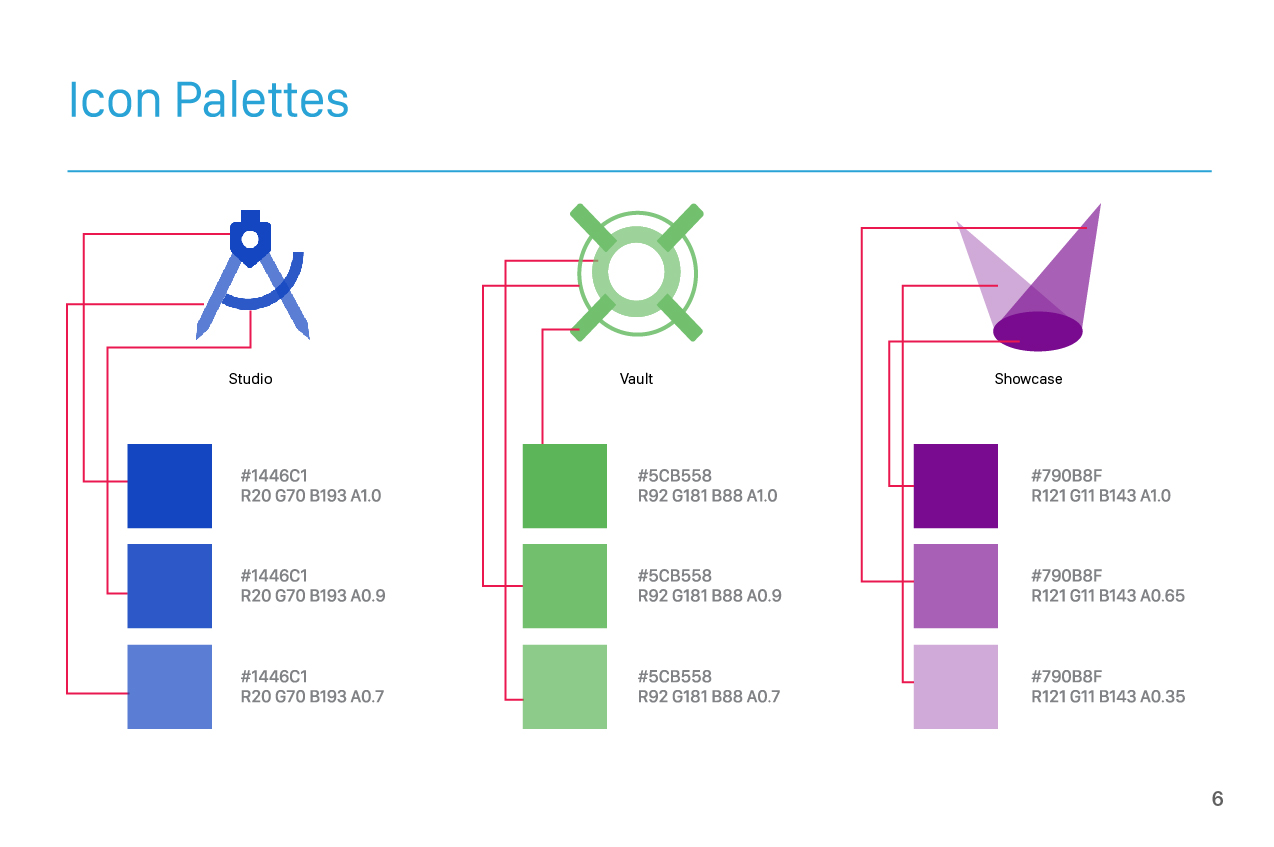

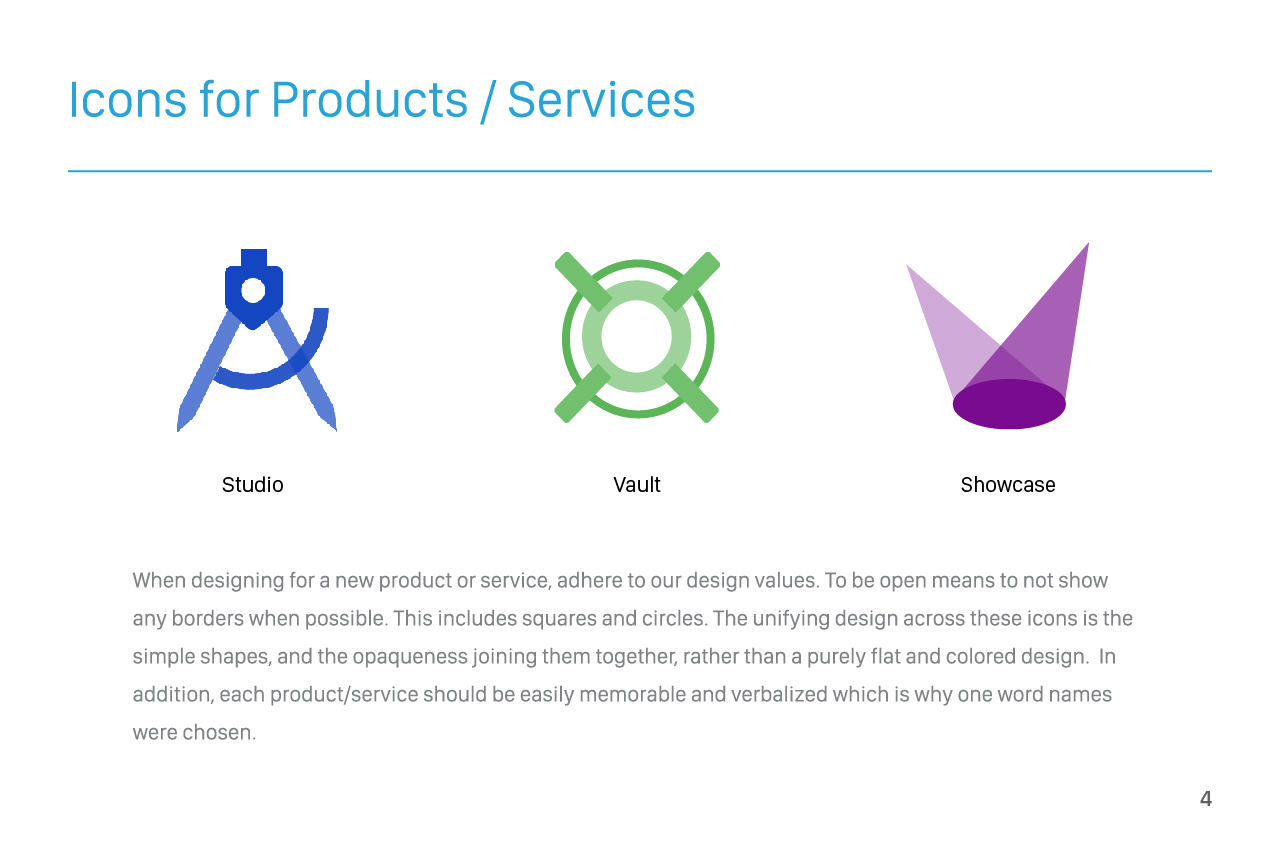

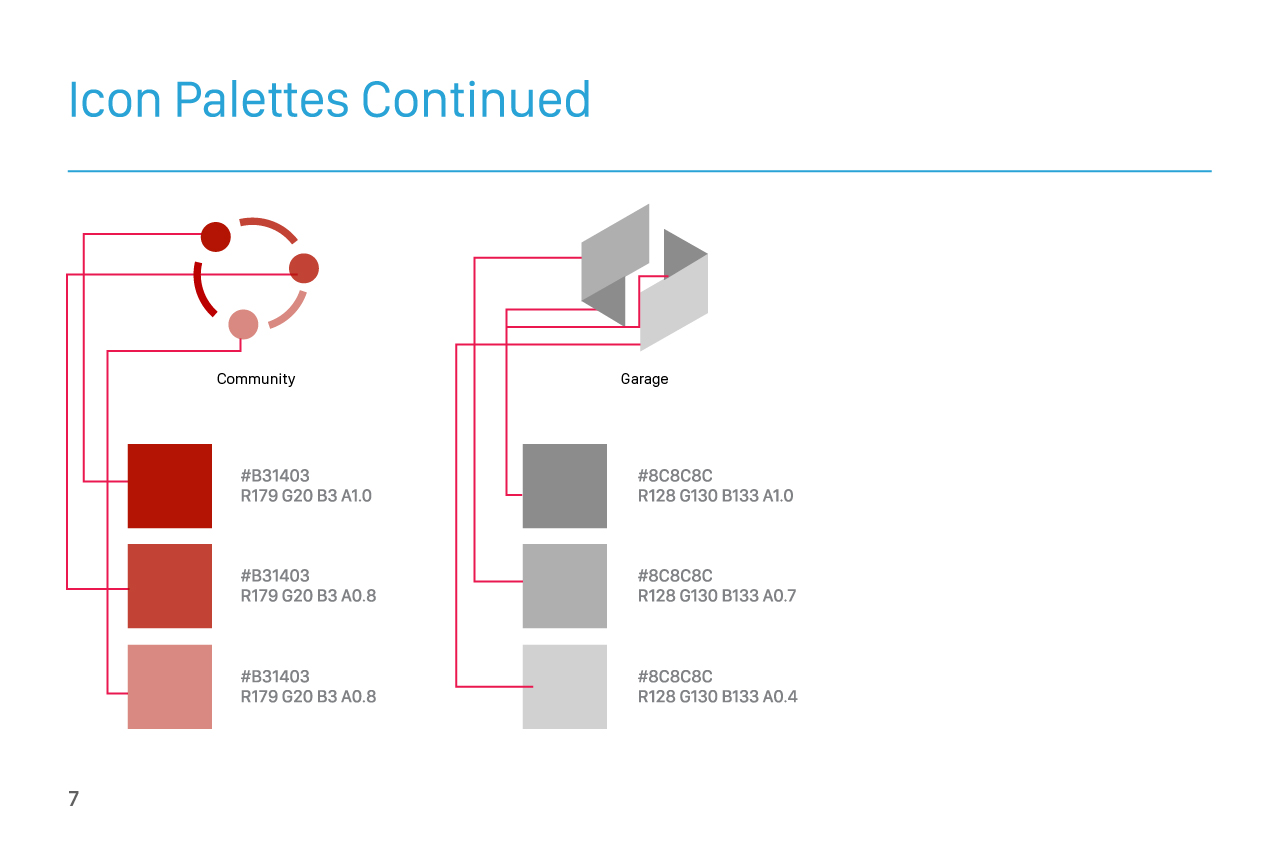

I worked closely with the co-founder and the marketing team to create a visual language that was consistent with the company's message and values. I worked primarily on redesigning the existing logo, product platform, and the company website. I also did a lot of analysis and market research on potential competitors to come up with a consistent visual brand and language that catered to the North American market ahead of the product launch.

After testing various logos and colors out with the co-founders and marketing team, the final workmark used an edited open-sourced sans-serif font, and blue as its primary color. Colors that exuded a feeling of being corporate and professional. Modern, but also approachable and inviting.

I worked closely with the co-founder and the marketing team to create a visual language that was consistent with the company's message and values. I worked primarily on redesigning the existing logo, product platform, and the company website. I also did a lot of analysis and market research on potential competitors to come up with a consistent visual brand and language that catered to the North American market ahead of the product launch.

After testing various logos and colors out with the co-founders and marketing team, the final workmark used an edited open-sourced sans-serif font, and blue as its primary color. Colors that exuded a feeling of being corporate and professional. Modern, but also approachable and inviting.

I worked closely with the co-founder and the marketing team to create a visual language that was consistent with the company's message and values. I worked primarily on redesigning the existing logo, product platform, and the company website. I also did a lot of analysis and market research on potential competitors to come up with a consistent visual brand and language that catered to the North American market ahead of the product launch.

After testing various logos and colors out with the co-founders and marketing team, the final workmark used an edited open-sourced sans-serif font, and blue as its primary color. Colors that exuded a feeling of being corporate and professional. Modern, but also approachable and inviting.

I worked closely with the co-founder and the marketing team to create a visual language that was consistent with the company's message and values. I worked primarily on redesigning the existing logo, product platform, and the company website. I also did a lot of analysis and market research on potential competitors to come up with a consistent visual brand and language that catered to the North American market ahead of the product launch.

After testing various logos and colors out with the co-founders and marketing team, the final workmark used an edited open-sourced sans-serif font, and blue as its primary color. Colors that exuded a feeling of being corporate and professional. Modern, but also approachable and inviting.

I worked closely with the co-founder and the marketing team to create a visual language that was consistent with the company's message and values. I worked primarily on redesigning the existing logo, product platform, and the company website.

I also did a lot of analysis and market research on potential competitors to come up with a consistent visual brand and language that catered to the North American market ahead of the product launch.

After testing various logos and colors out with the co-founders and marketing team, the final workmark used an edited open-sourced sans-serif font, and blue as its primary color. Colors that exuded a feeling of being corporate and professional. Modern, but also approachable and inviting.

Primary and Alternate wordmarks

Primary and Alternate Logos

Primary and Alternate wordmarks

Screenshot of CUCM with Navigation

Primary and Alternate wordmarks

FPK STUDIO

FPK STUDIO

FPK STUDIO

FKP STUDIO

FPK STUDIO

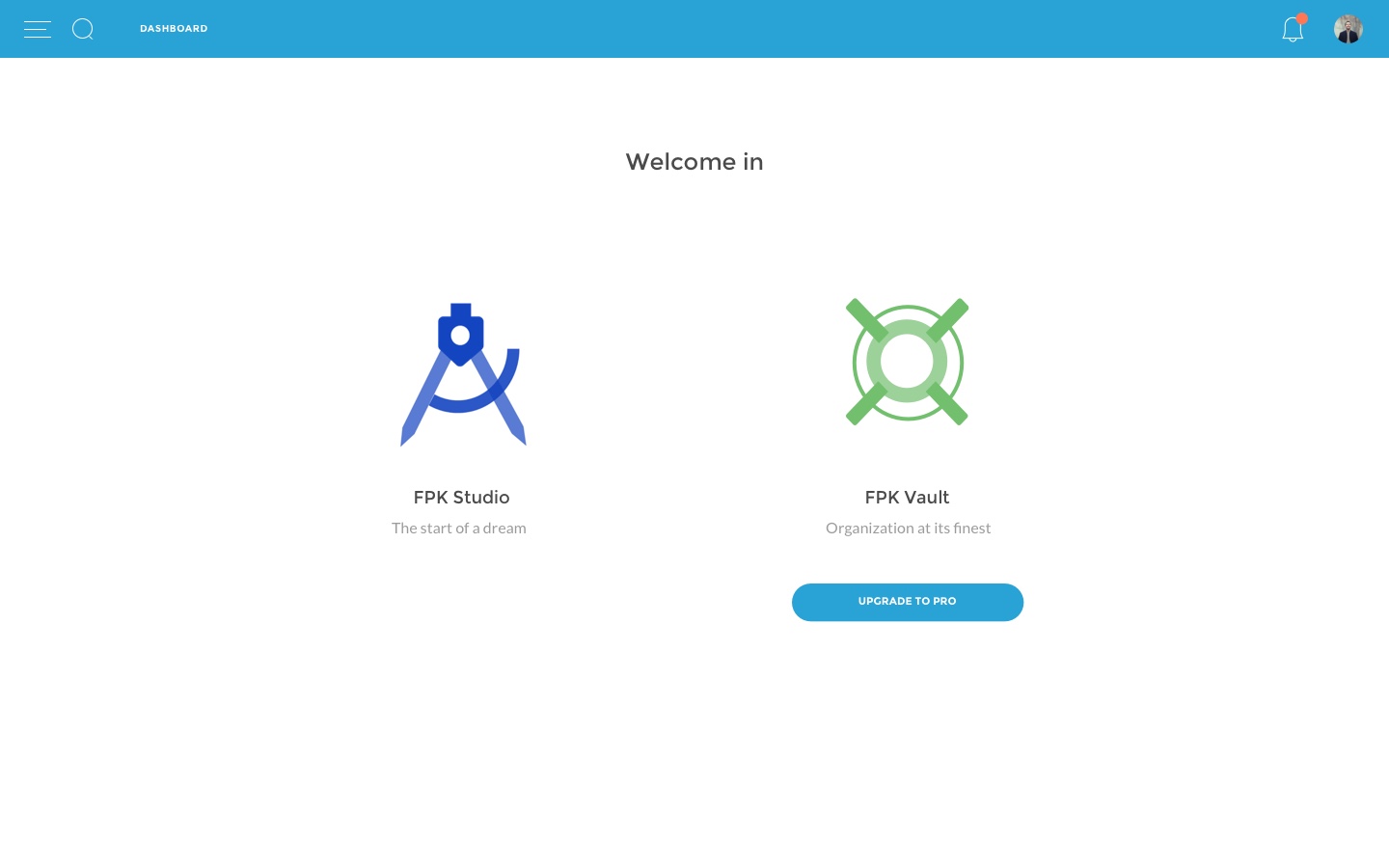

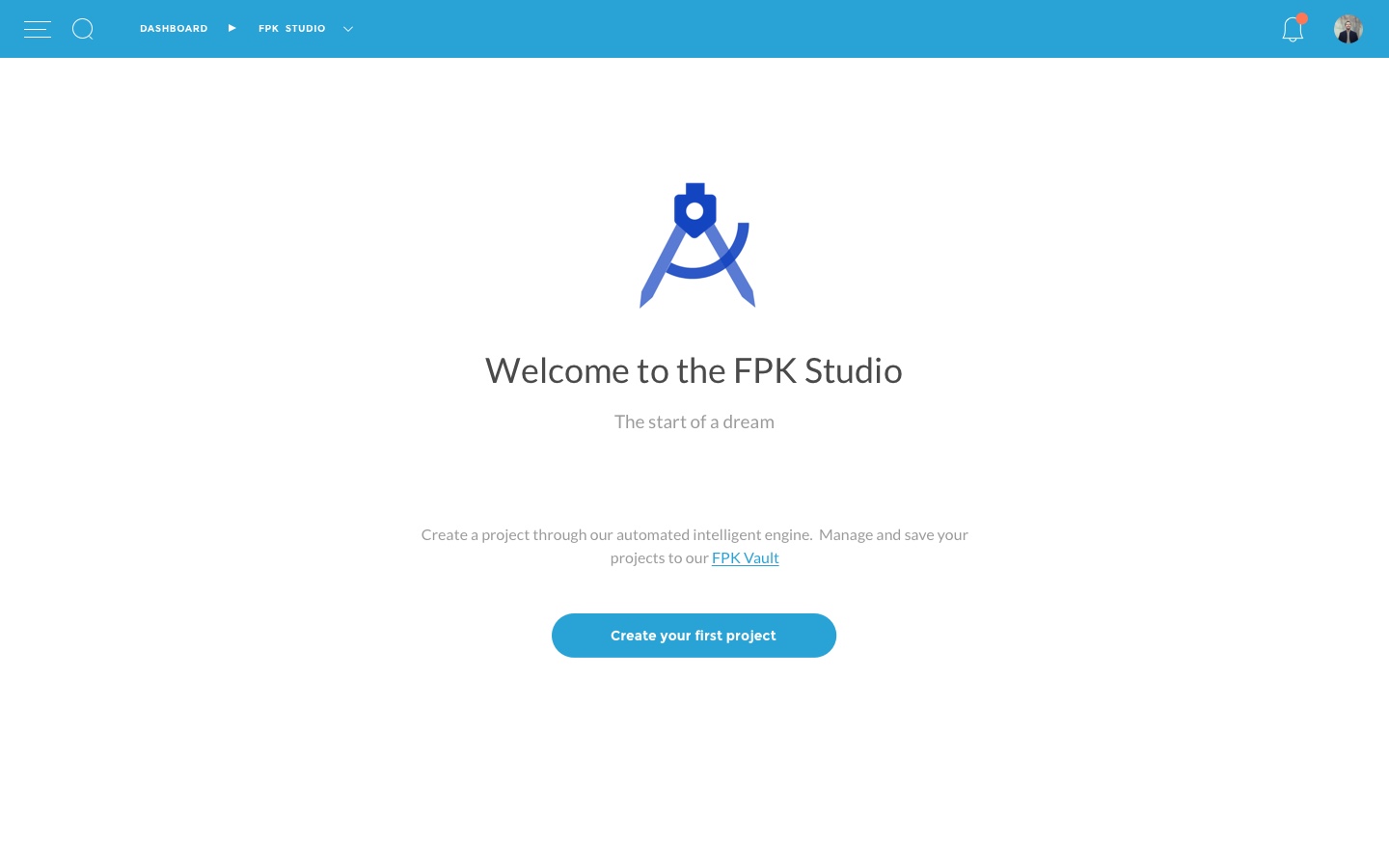

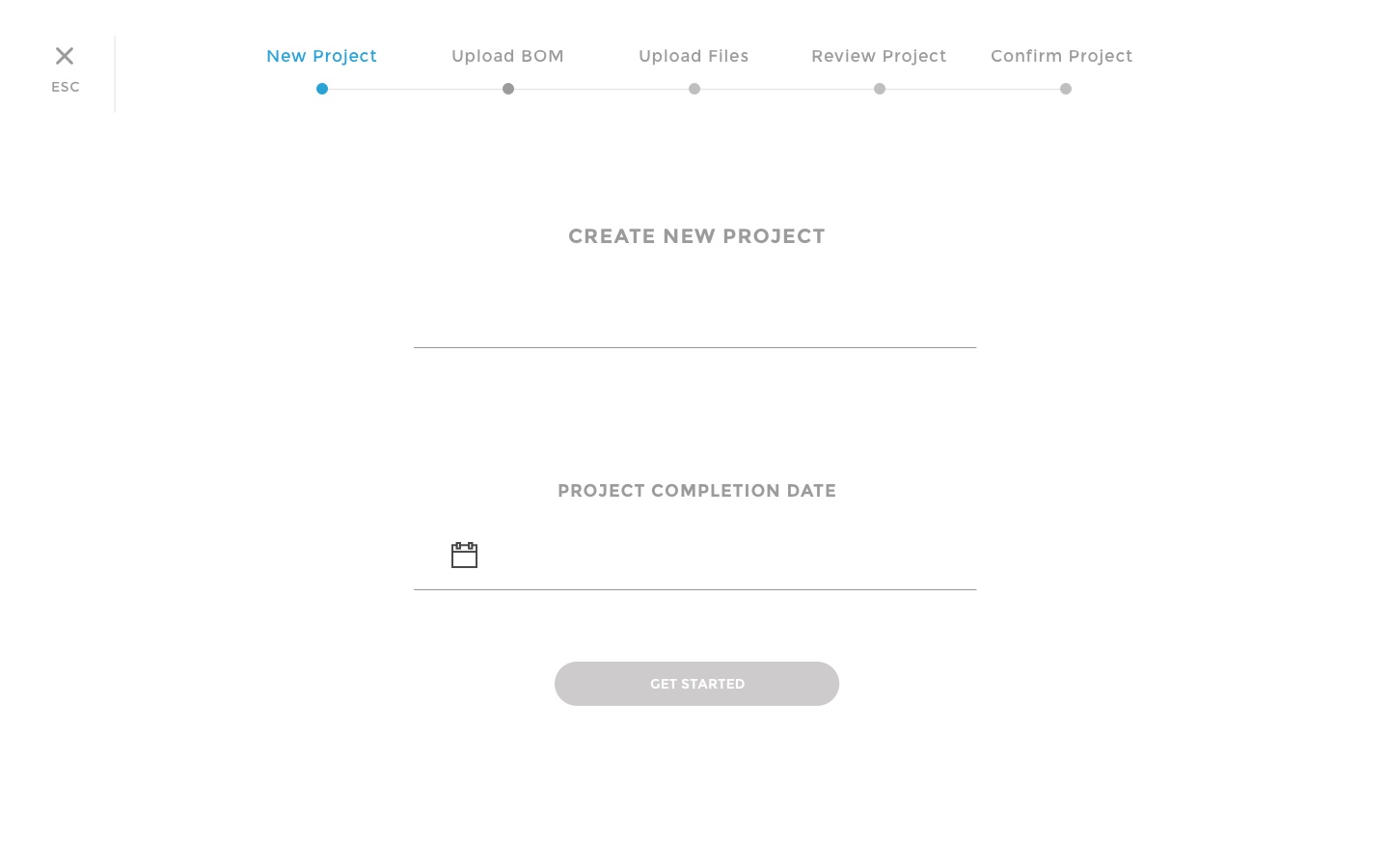

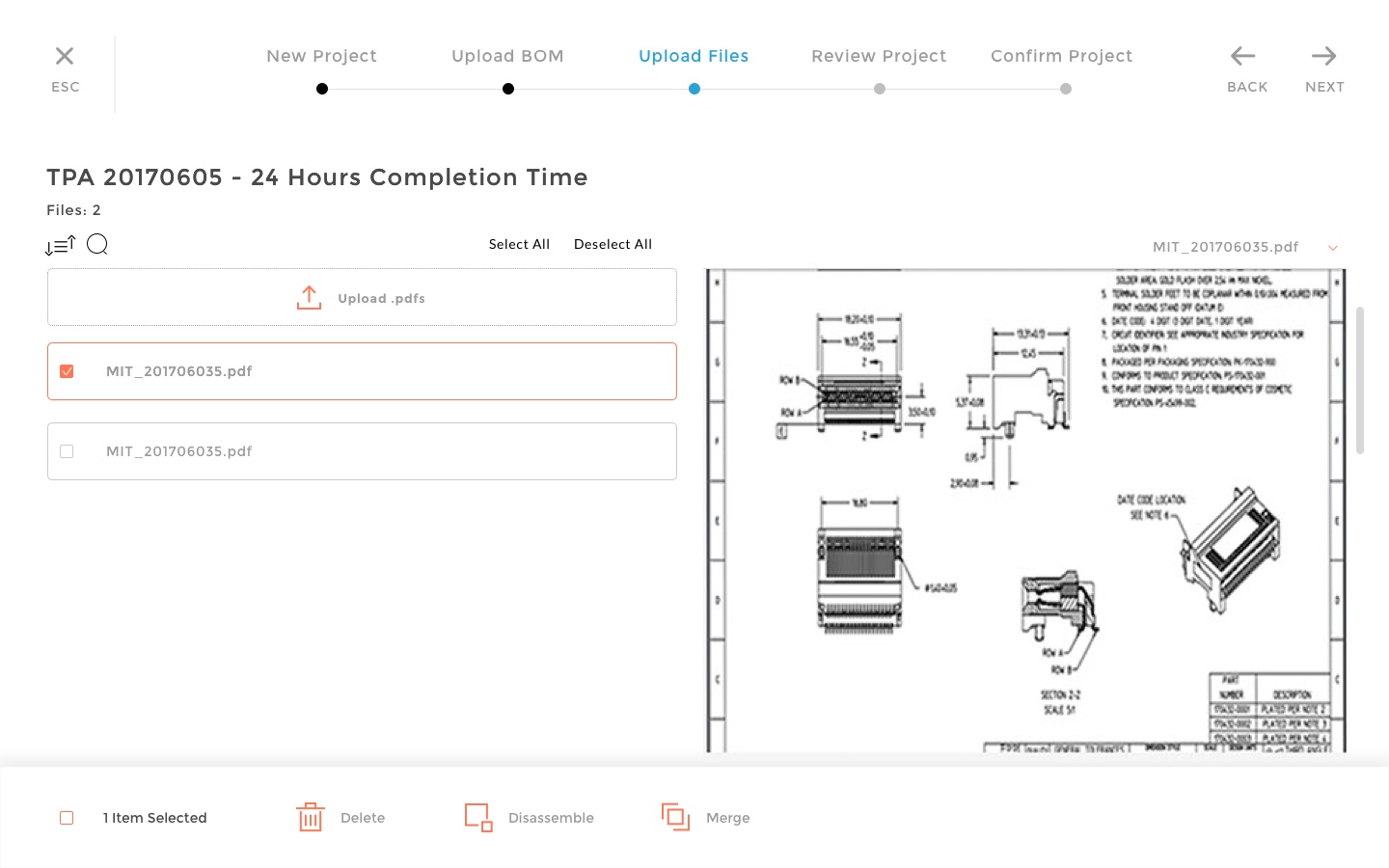

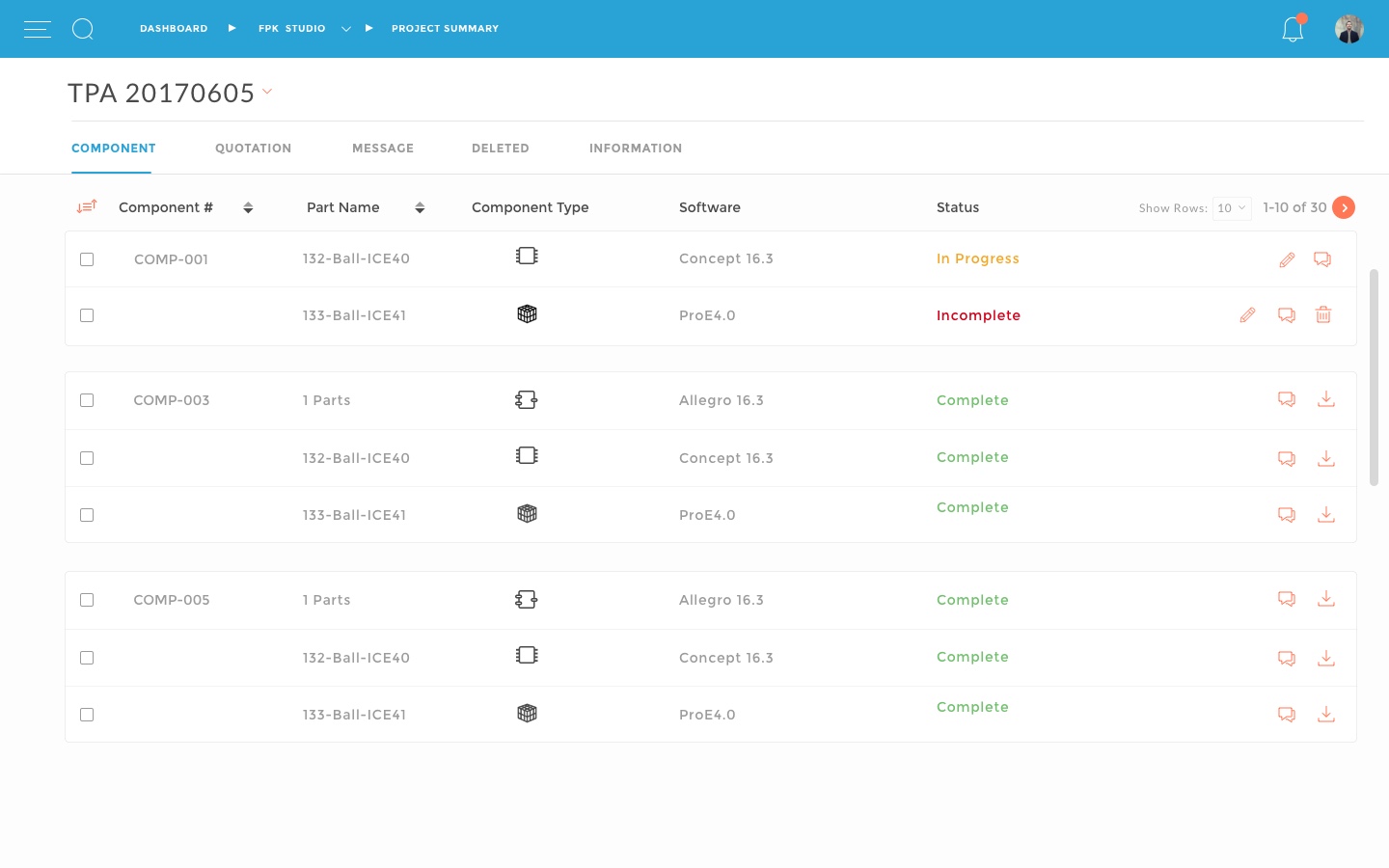

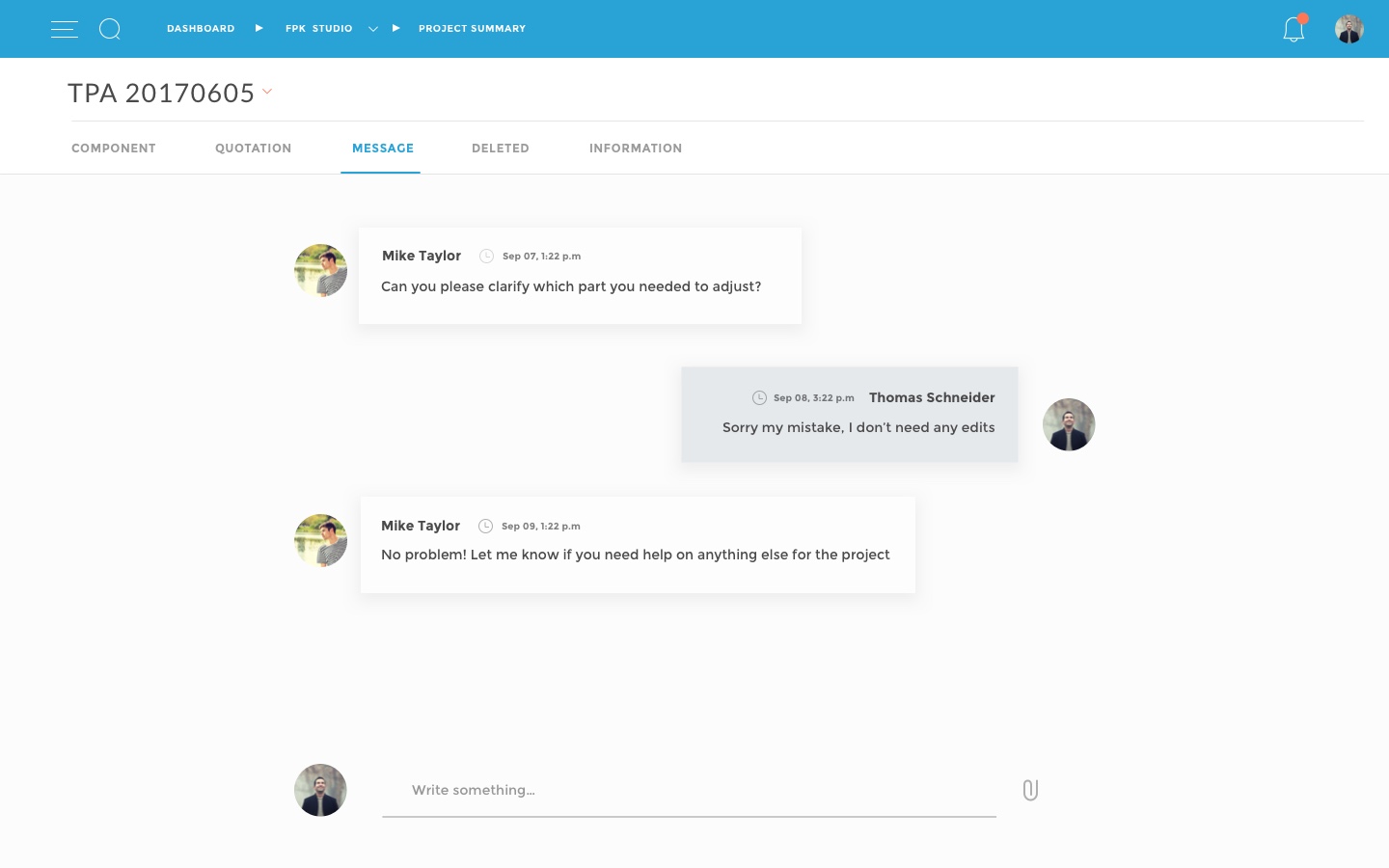

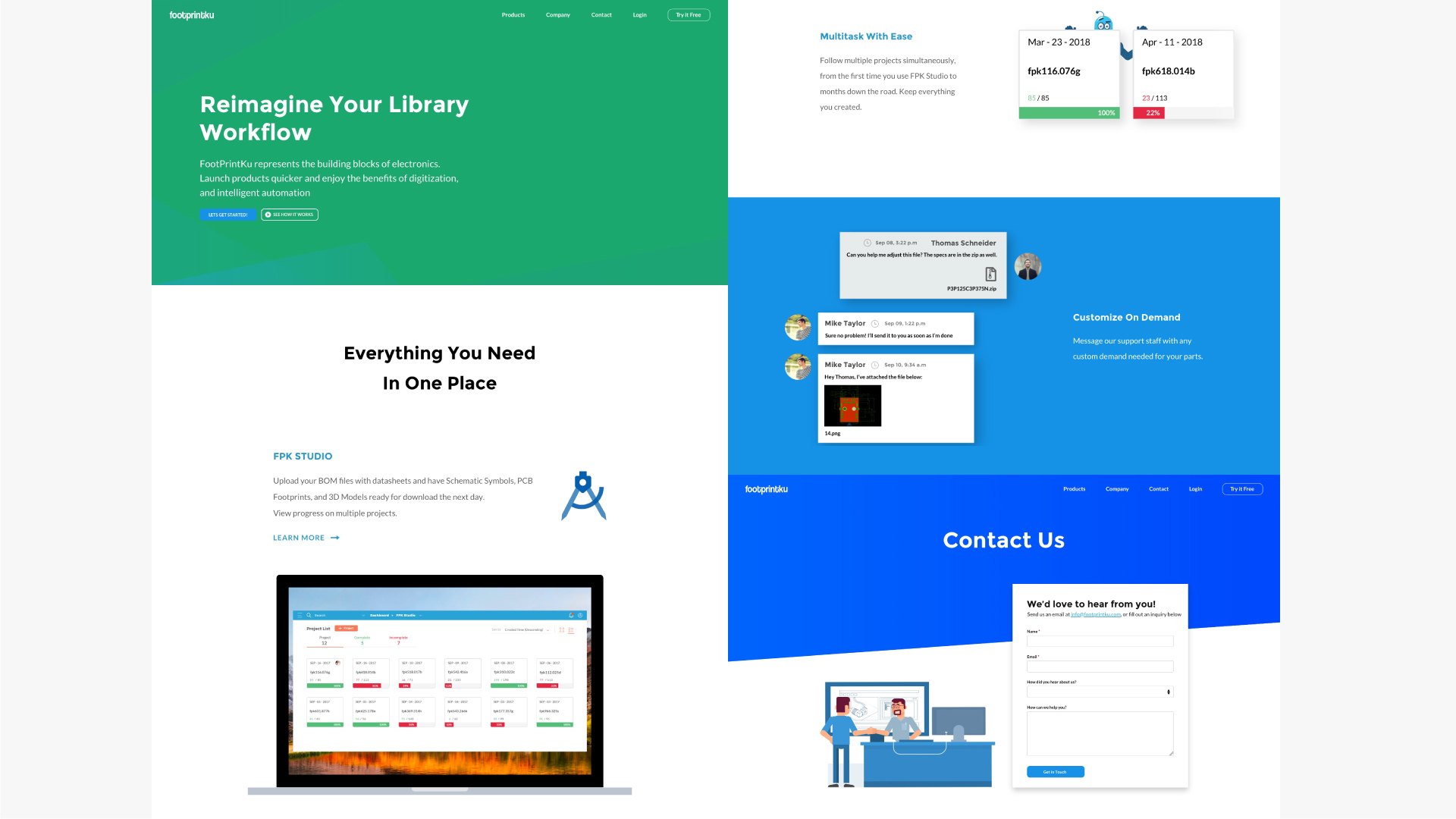

FootPrintKu launched with two products in mind as a bundle, the first was their FPK Studio product — which was built for hardware engineers. Users can upload electronic parts requests through a wizard to the FPK Studio and the system will complete the work and QA the parts with automation software.

They can track the status of their requests, and message the QA team if there's any issues or special requests regarding their parts. Accurate footprints, symbols and 3-D models will be ready in days. The platform also delivers real time status tracking for all requests.

The product had to be easily used by non-experts, which was the product design emphasized the use of a step by step wizard.

FootPrintKu launched with two products in mind as a bundle, the first was their FPK Studio product — which was built for hardware engineers. Users can upload electronic parts requests through a wizard to the FPK Studio and the system will complete the work and QA the parts with automation software.

They can track the status of their requests, and message the QA team if there's any issues or special requests regarding their parts. Accurate footprints, symbols and 3-D models will be ready in days. The platform also delivers real time status tracking for all requests.

The product had to be easily used by non-experts, which was the product design emphasized the use of a step by step wizard.

FootPrintKu launched with two products in mind as a bundle, the first was their FPK Studio product — which was built for hardware engineers. Users can upload electronic parts requests through a wizard to the FPK Studio and the system will complete the work and QA the parts with automation software.

They can track the status of their requests, and message the QA team if there's any issues or special requests regarding their parts. Accurate footprints, symbols and 3-D models will be ready in days. The platform also delivers real time status tracking for all requests.

The product had to be easily used by non-experts, which was the product design emphasized the use of a step by step wizard.

FootPrintKu launched with two products in mind as a bundle, the first was their FPK Studio product — which was built for hardware engineers. Users can upload electronic parts requests through a wizard to the FPK Studio and the system will complete the work and QA the parts with automation software.

They can track the status of their requests, and message the QA team if there's any issues or special requests regarding their parts. Accurate footprints, symbols and 3-D models will be ready in days. The platform also delivers real time status tracking for all requests.

The product had to be easily used by non-experts, which was the product design emphasized the use of a step by step wizard.

FootPrintKu launched with two products in mind as a bundle, the first was their FPK Studio product — which was built for hardware engineers. Users can upload electronic parts requests through a wizard to the FPK Studio and the system will complete the work and QA the parts with automation software.

They can track the status of their requests, and message the QA team if there's any issues or special requests regarding their parts. Accurate footprints, symbols and 3-D models will be ready in days. The platform also delivers real time status tracking for all requests.

The product had to be easily used by non-experts, which was the product design emphasized the use of a step by step wizard.

FPK VALUT

FPK VAULT

FPK VAULT

FPK VAULT

FPK VAULT

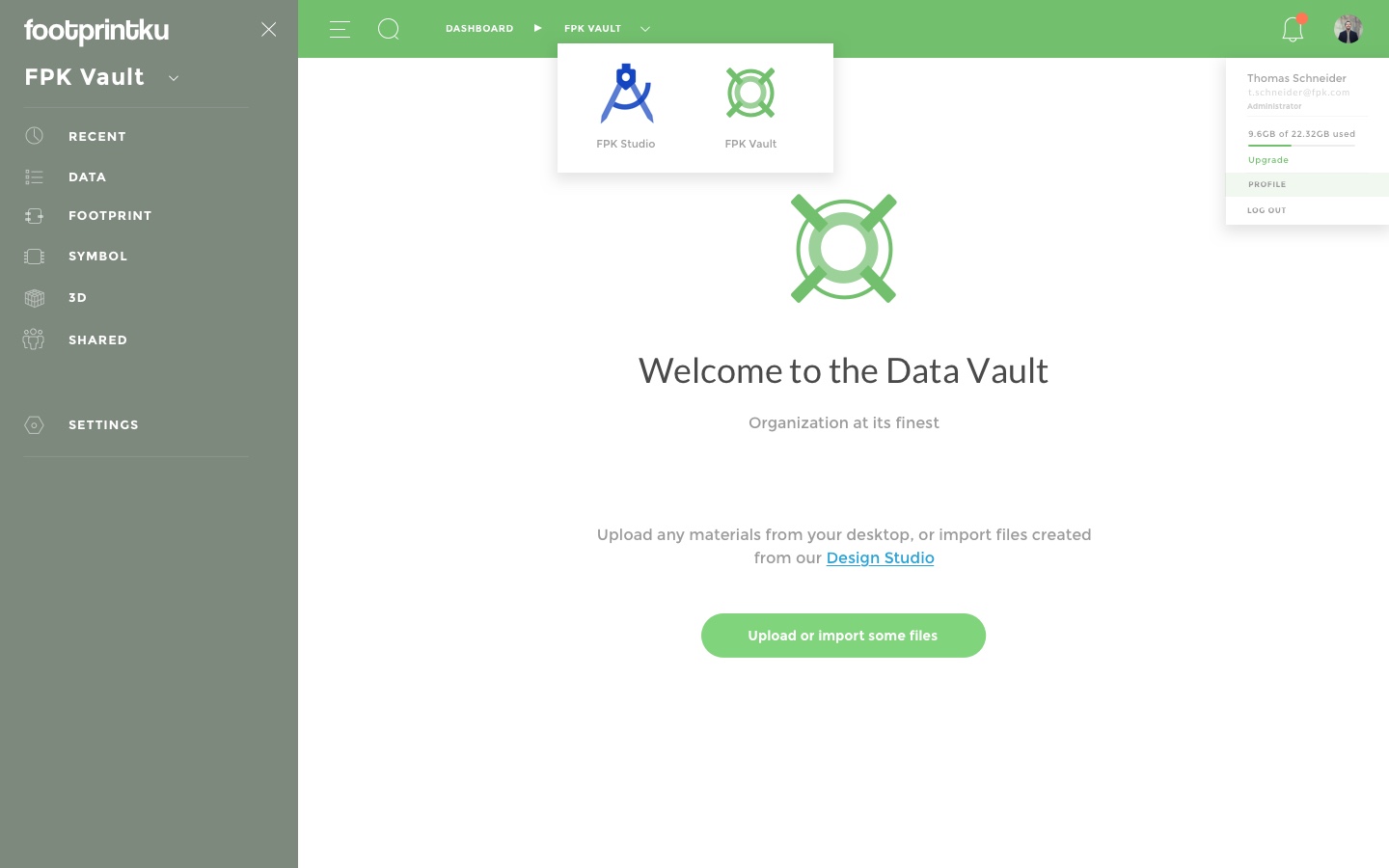

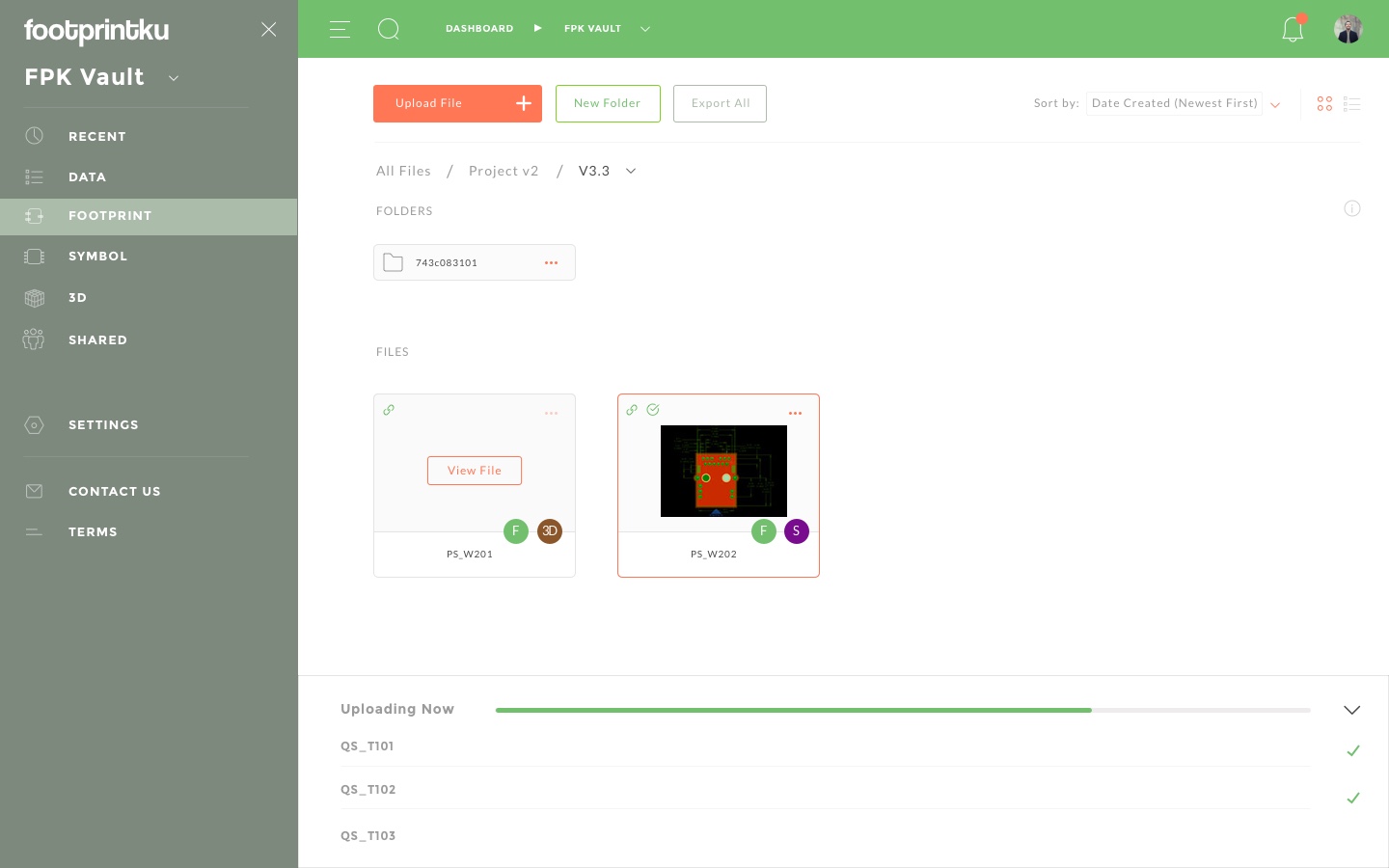

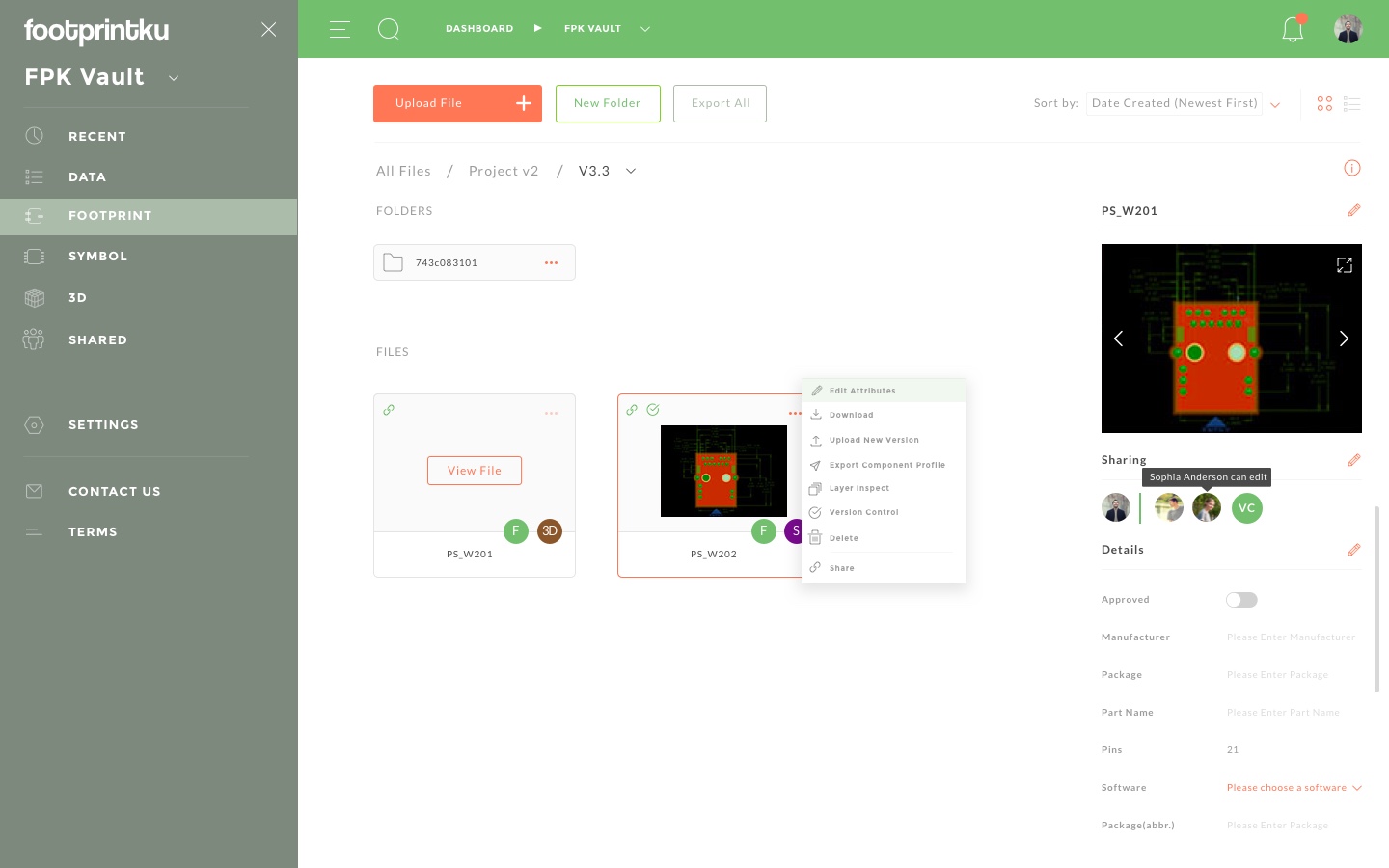

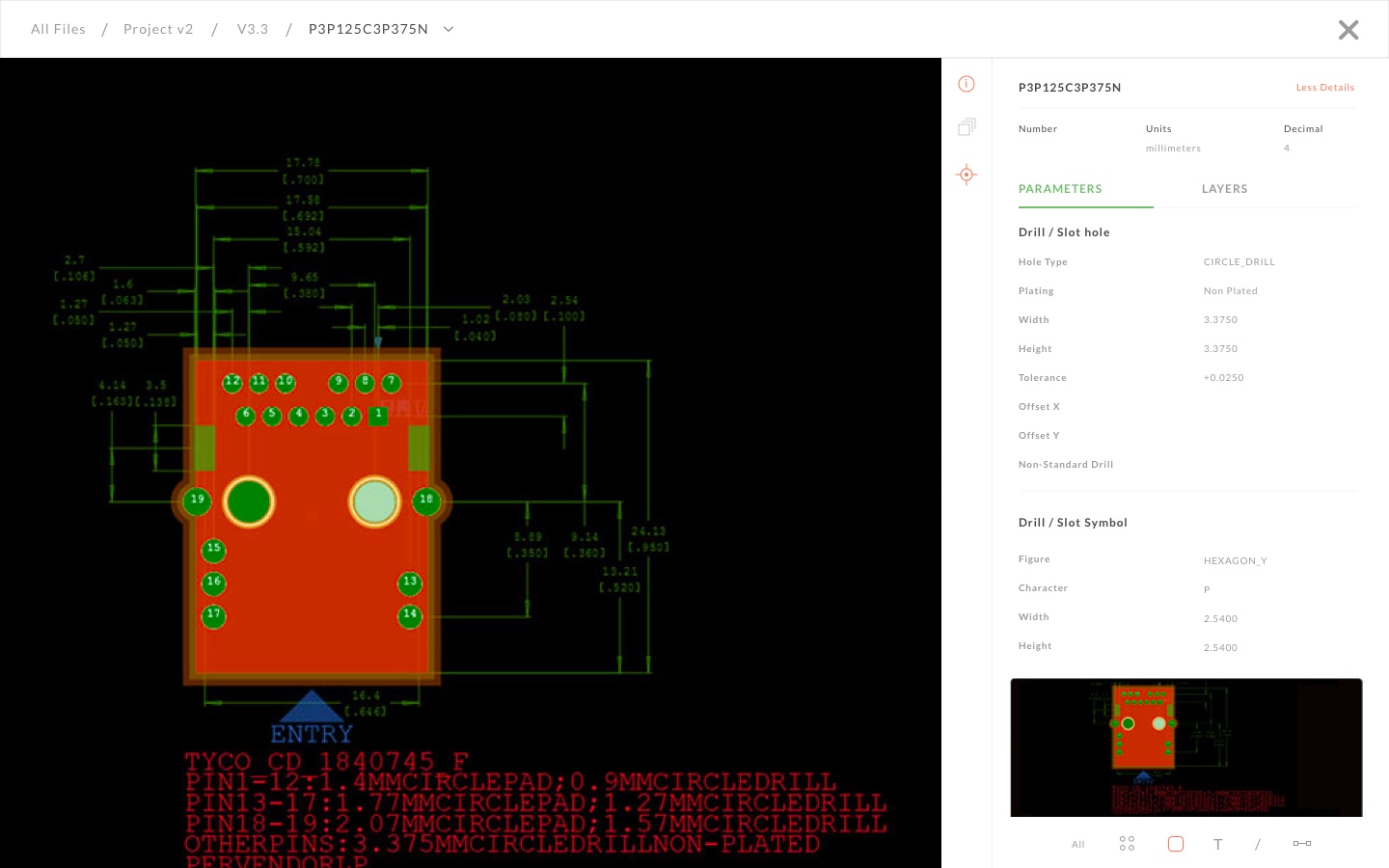

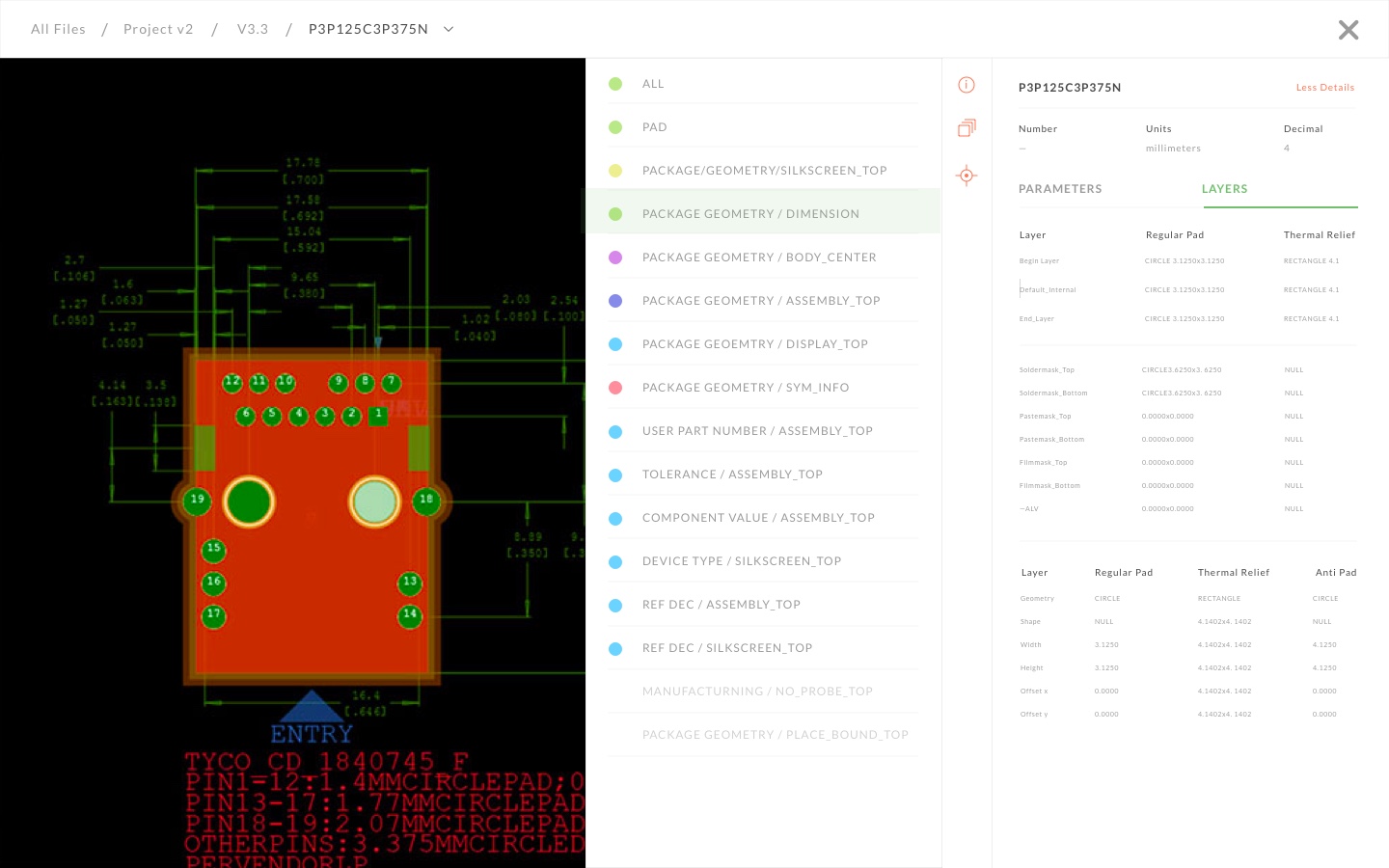

The Vault was the second product FootPrintKu was launching, a cloud storage that kept track of all the schematics created through the Studio product. It was designed to meet the needs of hardware librarians, those who kept track of the different schematics and parts needed for hardware design.

Vault allowed users to securely store, preview, edit and search their design library from anywhere using advanced search parameters. All files are kept in the cloud, and file changes and updates are kept current and accurate through version control. No additional tools or licenses are required to view them unlike the current hardware design process — where costly licenses are needed for proprietary file formats.

The Vault was the second product FootPrintKu was launching, a cloud storage that kept track of all the schematics created through the Studio product. It was designed to meet the needs of hardware librarians, those who kept track of the different schematics and parts needed for hardware design.

Vault allowed users to securely store, preview, edit and search their design library from anywhere using advanced search parameters. All files are kept in the cloud, and file changes and updates are kept current and accurate through version control. No additional tools or licenses are required to view them unlike the current hardware design process. Where costly licenses are needed for proprietary file formats.

The Vault was the second product FootPrintKu was launching, a cloud storage that kept track of all the schematics created through the Studio product. It was designed to meet the needs of hardware librarians, those who kept track of the different schematics and parts needed for hardware design.

Vault allowed users to securely store, preview, edit and search their design library from anywhere using advanced search parameters. All files are kept in the cloud, and file changes and updates are kept current and accurate through version control. No additional tools or licenses are required to view them unlike the current hardware design process. Where costly licenses are needed for proprietary file formats.

The Vault was the second product FootPrintKu was launching, a cloud storage that kept track of all the schematics created through the Studio product. It was designed to meet the needs of hardware librarians, those who kept track of the different schematics and parts needed for hardware design.

Vault allowed users to securely store, preview, edit and search their design library from anywhere using advanced search parameters. All files are kept in the cloud, and file changes and updates are kept current and accurate through version control. No additional tools or licenses are required to view them unlike the current hardware design process. Where costly licenses are needed for proprietary file formats.

The Vault was the second product FootPrintKu was launching, a cloud storage that kept track of all the schematics created through the Studio product. It was designed to meet the needs of hardware librarians, those who kept track of the different schematics and parts needed for hardware design.

Vault allowed users to securely store, preview, edit and search their design library from anywhere using advanced search parameters. All files are kept in the cloud, and file changes and updates are kept current and accurate through version control. No additional tools or licenses are required to view them unlike the current hardware design process. Where costly licenses are needed for proprietary file formats.

BRANDING

BRANDING

BRANDING

BRANDING

BRANDING

Besides redesigning the user interface, I played a key role in marketing and customer research for FootPrintKu’s product. I worked with the co-founders to figure out which marketing agencies could best help market our product. I eventually collaborated with The Stephenz Group to identify market potential and business development opportunities. I also worked closely with the creative team at Digital Brew to create an animated video and mascot that explained FootPrintKu’s platform. Some branding I did for the company include tradeshow banners, flyers, business cards, and promotional materials.

Besides redesigning the user interface, I played a key role in marketing and customer research for FootPrintKu’s product. I worked with the co-founders to figure out which marketing agencies could best help market our product. I eventually collaborated with The Stephenz Group to identify market potential and business development opportunities. I also worked closely with the creative team at Digital Brew to create an animated video and mascot that explained FootPrintKu’s platform. Some branding I did for the company include tradeshow banners, flyers, business cards, and promotional materials.

Besides redesigning the user interface, I played a key role in marketing and customer research for FootPrintKu’s product. I helped interview different marketing vendors and collaborated with The Stephenz Group to identify market potential and business development opportunities. I also worked closely with the creative team at Digital Brew to create an animated video and mascot that explained FootPrintKu’s platform. Some branding I did for the company include tradeshow banners, flyers, business cards, and promotional materials.

Besides redesigning the user interface, I played a key role in marketing and customer research for FootPrintKu’s product. I helped interview different marketing vendors and collaborated with The Stephenz Group to identify market potential and business development opportunities.

I also worked closely with the creative team at Digital Brew to create an animated video and mascot that explained FootPrintKu’s platform. Some branding I did for the company include tradeshow banners, flyers, business cards, and promotional materials.

Besides redesigning the user interface, I played a key role in marketing and customer research for FootPrintKu’s product. I helped interview different marketing vendors and collaborated with The Stephenz Group to identify market potential and business development opportunities.

I also worked closely with the creative team at Digital Brew to create an animated video and mascot that explained FootPrintKu’s platform. Some branding I did for the company include tradeshow banners, flyers, business cards, and promotional materials.

Product Launch Website

Product Launch Website

Product Launch Website

Product Launch Website

Popsocket Design

Popsocket Design

Popsocket Design

Popsocket Design

Booth at Electronic Tradeshow with marketing materials

Booth at Electronic Tradeshow with marketing materials

Booth at Electronic Tradeshow with marketing materials

Booth at Electronic Tradeshow with marketing materials

Mascot

Mascot

Mascot

Mascot

FINAL TAKEAWAYS

IMPACT

IMPACT

IMPACT

IMPACT

The product launched successfully and is being used in partnership with a lot of hardware design companies like Cadence and Microsoft. A lot of the guidelines and design conventions I created are still in use even for future product roadmaps. Unfortunately due to NDAs, I am unable to show the difference between the original user interface (as it was being piloted by hardware companies), and the new redesign.

The product launched successfully and is being used in partnership with a lot of hardware design companies like Cadence and Microsoft. A lot of the guidelines and design conventions I created are still in use even for future product roadmaps. Unfortunately due to NDAs, I am unable to show the difference between the original user interface (as it was being piloted by hardware companies), and the new redesign.

The product launched successfully and is being used in partnership with a lot of hardware design companies like Cadence and Microsoft. A lot of the guidelines and design conventions I created are still in use even for future product roadmaps. Unfortunately due to NDAs, I am unable to show the difference between the original user interface (as it was being piloted by hardware companies), and the new redesign.

The product launched successfully and is being used in partnership with a lot of hardware design companies like Cadence and Microsoft. A lot of the guidelines and design conventions I created are still in use even for future product roadmaps. Unfortunately due to NDAs, I am unable to show the difference between the original user interface (as it was being piloted by hardware companies), and the new redesign.

The product launched successfully and is being used in partnership with a lot of hardware design companies like Cadence and Microsoft. A lot of the guidelines and design conventions I created are still in use even for future product roadmaps.

Unfortunately due to NDAs, I am unable to show the difference between the original user interface (as it was being piloted by hardware companies), and the new redesign.